The Environment and Ultra3X™

COMPLETE OIL, FUEL and HYDROCARBON SPILL CLEAN UP-WITHOUT CHEMICALS-100% REMOVAL---Recovery of Hydrocarbons for Re-sale and Re-Use! |

TRUE RECYCLING of PRODUCTION WATER FROM OIL and GAS OPERATIONS. NO CHEMICALS and NO MEDIA USED. Cheap and Efficient. |

UNITS AVAILABLE NOW FOR DEPLOYMENT INTO THE FIELD FOR CLEAN UP OPERATIONS.

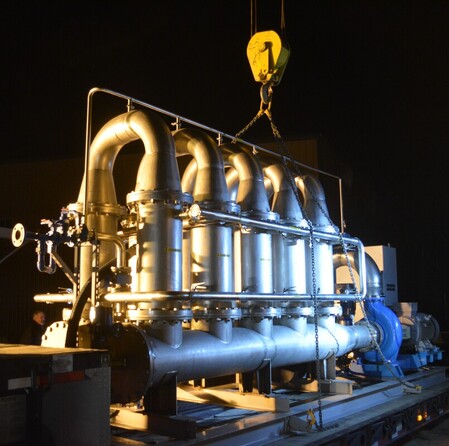

Ultra3x has large MOR units capable of processing 8-10,000 bpd. Once delivered these units can be up and operating within hours. Transforming hydrocarbon laden water into sparkling clean water free of hydrocarbons and recovering the valuable hydrocarbons for use.

"Solving the technical and economic challenges around managing the millions of gallons of water used to properly fracture tight oil and gas wells is the holy grail of the industry.”

Steve Mueller, CEO

Southwestern Energy

Steve Mueller, CEO

Southwestern Energy

Ultra3X™ Will Clean up the Environment Effectively and Efficiently

Ultra3X™ units and even full scale plants can assist in solving all of these problems. We can recycle nearly 100% of the waste water with a minimal environmental footprint. Our units are run on a standard 3 phase 48 KVA per unit so there are no additional emissions. The only disposable is from the clean out of the sand tank to get the sand, grit and dirt. All additional solid wastes will be disposed of by Ultra3X™. Hydrocarbons removed from the water are recovered and re-used. Depending on the amount of hydrocarbon recovered the value of the hydrocarbons recovered will help offset the cost of the recovery.